OUR SERVICES

1. Drawing Services

MCPL offer unique drawing services for mechanical engineering department.

Our expert CAD drafters can create drawing with high precision and details from hand-drawn sketches or any other reference, engineering blueprints, and engineering PDF documents. Our service team served for mechanical engineers, manufacturers, fabricators, innovators, and production teams.

We provide the following mechanical drawing services

- Prepare plant layout / Equipment layout / Marking drawings / Cut out drawings.

- Prepare fabrication detail drawing for plant piping. (Isometric / spool drawing / general arrangement drawing / etc.)

- Prepare IBR Isometric drawing.

- Prepare fabrication detail drawing for steel structure (Beam, column, platform, pipe rack, etc.)

- Preparation of shop fabrication drawing for chemical plant equipment, pressure vessels, heat exchanger column, etc.

- Prepare instrument HOOK-UP drawing.

- Prepare electrical plant layout drawing.

- Reverse engineering.

- Audit related drawing preparation (Plot plan, equipment drawings, factory layout, etc.)

- All type of site as built drawing activity / new facility add in existing plant / site measurement / etc.

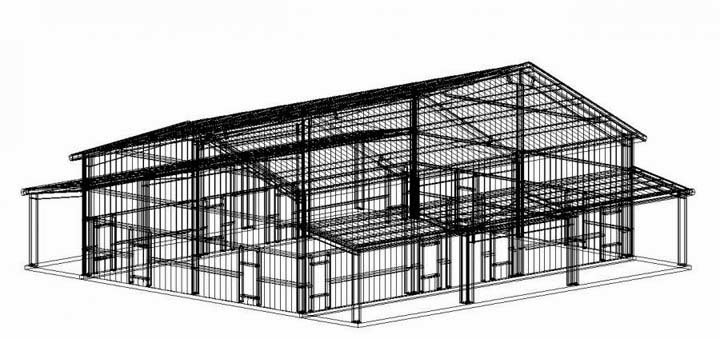

2. Steel Structure Design

Our company is very reliable for steel structure design; our first goal is to provide a quality service on time all over India. We have been providing unique designs since 2022 and have completed 100 successful projects.

Industry: We work for all types of industries, such as power, cement, chemical oil, and gas.

Code and Standard: We follow Indian Standard or according to the client’s requirements.

3. Industrial Piping Design

MCPL provides industrial piping solutions for all Indian industries like power, water, air, oil, and gas. And we use international codes and standards or according to the client’s requirements to meet those efficient services.

MCPL provides piping design consultants who bring together value from 2D to 3D piping layout to conduct pipe stress analysis and studies related to flexibility analysis, which ensures reliability, safety, and simulates the piping systems.

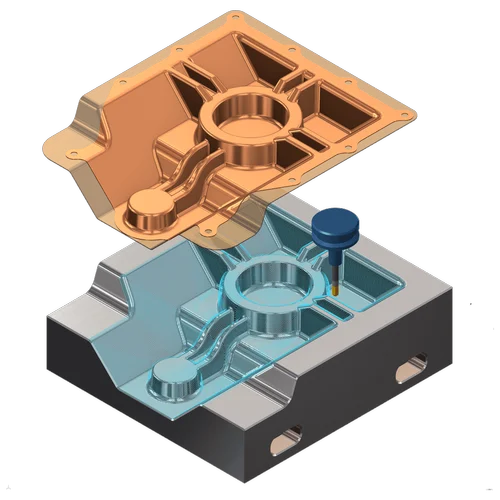

4. Pressure Vessel Design

MET Creativity provide complete design support for pressure vessel fabrication companies and design engineering firms to develop robust pressure vessel drawing and designs to avoid accidents.

Our pressure vessel design services include development of pressure vessel AutoCAD drawings, 3D models in Solid Work, custom vessel modelling using inventor, and design analysis of various type of industrial vessels.

We ensure that the final designed and fabricated pressure vessel meet the safety standards and avoid any operational hazards by developing the fabrication drawings that adhere to ASME codes written under section VIII Division 2.

We are the leading pressure vessel design company, based in India, delivering pressure vessel design, analysis, proofs of designs, FEA and CFD plots, temperature and velocity profile, and inspection to ensure design stability. We help fabricators avoid redesigning and help save the costs of reworks during manufacturing

Our service area

- Pressurized tanks and settler vessels

- Boilers and heat exchangers

- Steam drums, knock out pots

- Storage tanks: Above the ground, flash tanks

- Oil and gas pressure vessels

- Processing tanks, cooling tanks and heaters

- Jacketed vessels, silos, columns etc.

- Compressed air tanks, filter tanks

- Cyclone separators, filters, blow down tanks, etc.

Code and Standard: ASME Boiler and Pressure Vessel Code or according to the client’s requirements.

5. SolidWorks Solution

We are providing SolidWorks design services include specific feature sets that are ideal for industrial designers, product manufacturers, design engineers, and others who are looking to design and create exciting products, like machine parts, piping, pressure vessels, structures, etc., and they are complete with a short timeframe.

6. Reverse Engineering

MET Creativity facilitate the reverse engineering of entire machines, allowing for part replacement, upgrades, and automation to be added. A rebuild aims to ensure that all components are in optimal working condition while also restoring any lost performance of efficiency due to general wear and tear. Machine rebuilds are carried out by certified technicians who use specialized tools and custom CNC machining techniques to restore performance of efficiency.

7. Fabrication and Erection

- Fabrication and erection of structures

- Fabrication and erection of high and low pressure piping.

- Fabrication and erection of tanks and vessels.